The main surface treatment methods for guardrail beam

The main surface treatment methods for guardrail beam include hot-dip galvanizing and spray painting.

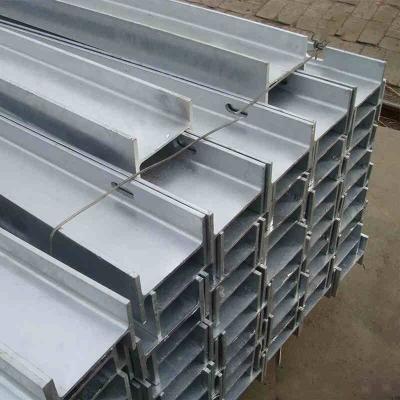

Hot dip galvanizing is a common surface treatment method for guardrail beam. Through a series of process steps such as acid washing, water washing, adding plating solution, drying, hanging plating, cooling, chemical treatment, cleaning, polishing, etc., a zinc layer is attached to the surface of steel components, achieving the goals of anti-corrosion and anti scratch, long oxidation time, and good anti-corrosion and anti rust effects.

Spray molding, on the other hand, uses an electrostatic generator to charge plastic powder and adsorb it onto the surface of an iron plate. After baking, the powder melts and adheres to the metal surface. This processing method is often used for indoor boxes, and the paint film can present a flat or matte effect. In the application of guardrail beam, spray coating is often combined with galvanizing process, such as cold galvanizing spray coating on steel plates or hot galvanizing spray coating on steel plates, to improve the corrosion resistance of guardrail beam.

Both of these surface treatment methods can effectively improve the corrosion resistance of guardrail beam, extend their service life, and also help improve the aesthetics of the guardrail beam. The specific choice of method needs to be comprehensively considered based on factors such as the usage environment and budget of the guardrail.